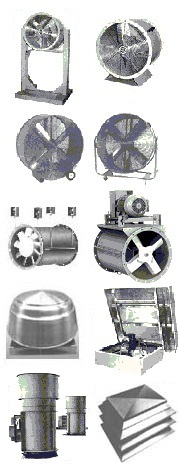

NIS-CO FANS AND BLOWERS

In

pactice this sulfur removal process requires a gas-tight, zero leakage,

high temperature and high pressure blower for intermittent duty that

must handle toxic gases and must be capable of being brought on line

immediately upon demand. To do this the following features on the

blower must be provided:

- Double welded casing

construction;

- Steam flows between the

housing walls to maintain a constant 285 F gas temperature inside the

fan (because below 285 F sulfur will change from a gaseous to a solid

state and will "freeze" to the blower surfaces causing damage or

destruction);

- A mechanical shaft seal with

heat tracing and purge by air or nitrogen;

- To assure tight tolerances

between the shaft and shaft seal, the housing should be supported at

the centerline, and grows concentric to the fan shaft when exposed to

heat.: since this support isolates housing from the drive and mounting

bases, housing thermal growth doesn't cause forces to be applied to

these bases.

- To prevent the shaft from

taking a permanent set when the blower is idle but still exposed to the

high temperature, a turning gear is provided to keep the blower

rotating at a very slow speed of 25 - 40 RPM; alternatively a VFD speed

control can be used